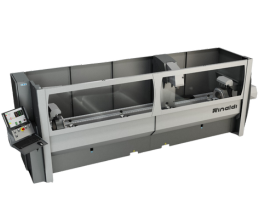

End milling machine INT 32 – 32A

Horizontal end milling machine with manual feed or semiautomatic in the “32A”.

The ‘high-speed spindle improves the quality of machining on painted profiles and at intermediate angles.

Performs milling at 90 ° and with variable angle from -45 ° to + 45 °.

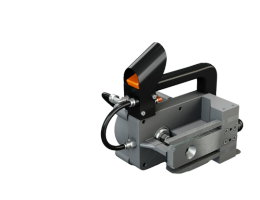

Quick tool change with pneumatic control.

Scratch-proof work

Protection of the working zone with wide internal visibility.

| Power supply treephase | 380/400-50-60 | Volt-Hz |

| Treephase motor power | 1.5 | kW |

| Spindle speed | 6000 | r.p.m. |

| Stroke axis X | 320 | mm |

| Clamp capacity (bxh) | 200x120 | mm |

| Maximum cutter diameter | 180 | mm |

| Milling angle | -45...+45 | ° |

| Weight | 180-190 | kg |

Sales and Customer Service:

Morning from 08:30 to 12:30

Afternoons from 14:00 to 18:00