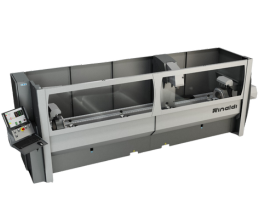

Copy router PAN 38L – 38Li

Manually controlled single-head copy router on base 3000 mm long, with manually movable unit and pneumatic clamping.

Semi-automatic head down feed with rapid approach device and chamber jump.

Pneumatically operated quick tool change (optional).

Steel up to 2 mm can be processed with standard equipment; with specific accessory stainless steel up to 1.5 mm.

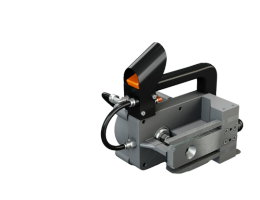

Pneumatic feeler with pneumatic traversing with 5 adjustable positions allows fast and precise machine set-up.

The vice table rotation system allows machining 3 faces of the profile without unclamping the vices or 4 faces by performing through machining.

The rotary movement from 0° to 180° maintains the same axis; the figure produced on the first face at 0° is at the same elevation as that reproduced on the opposite face at 180°. This system makes it possible to increase execution speed and accuracy, use shorter tool lengths and thus reduce

vibration and noise.

Pneumatically operated front work zone guard.

| Power supply treephase | 380/400-50/60 | Volt-Hz |

| Three-phase motor power (38L version) | 0.35/0.55 | kW |

| 2 Spindle speeds (38L version) | 3500 / 12000 | r.p.m. |

| Three-phase motor power (38LI version) | 1.1 | kW |

| 2 Spindle speeds (38LI version) | 3300 / 12000 | r.p.m. |

| X-Y- Z axis stroke | 2500 - 150 - 250 | mm |

| 90° clamp capacity (bxh) | 140x110 | mm |

| Tilting clamp table | 0 / 90 / 180 | ° |

| Maximum cutter diameter | 12 | mm |

| Diameter probe tips | 5 - 8 - 10 | mm |

| Weight | 680 | kg |

Sales and Customer Service:

Morning from 08:30 to 12:30

Afternoons from 14:00 to 18:00